DIY Plywood Garage Workshop Cabinets On A Budget

Save money and maximize space with our comprehensive DIY guide!

Keywords: DIY garage cabinets, plywood workshop cabinets, budget garage storage, cheap garage organization, building cabinets, garage workshop organization, plywood cabinet plans, DIY woodworking projects, affordable garage makeover, garage storage solutions, woodworking for beginners, cheap garage cabinets, inexpensive garage storage

Introduction:

A cluttered garage is the bane of any homeowner’s existence. Tools scattered everywhere, materials piled haphazardly, and a general sense of chaos can quickly turn your dream workshop into a frustrating obstacle. But what if you could conquer this clutter and create the organized, efficient workspace you’ve always wanted – without breaking the bank? The answer lies in the power of DIY: building your own plywood garage workshop cabinets. This comprehensive guide will walk you through every step, from planning and material selection to assembly and finishing, ensuring you achieve a professional-looking result on a budget.

Table of Content

Why Plywood? The Smart Choice for Budget-Conscious Builders:

Plywood emerges as the champion material for this project due to its affordability, strength, and versatility. Compared to solid wood, plywood offers significant cost savings, making it an ideal choice for budget-conscious DIYers. Its layered construction provides exceptional stability and resistance to warping, crucial for building sturdy cabinets that can withstand the rigors of a workshop environment. Furthermore, plywood’s smooth surface is easily workable, making it a joy to cut, sand, and finish.

Phase 1: Planning and Design – Laying the Foundation for Success:

Related Article Save money and maximize space with our comprehensive DIY guide!

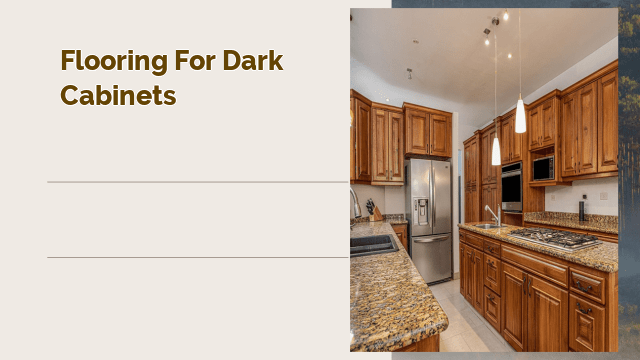

- flooring for dark cabinets

- Kitchens with Off White Cabinets

- Utensil Pull Out Cabinet: The Perfect Storage Solution for Your Kitchen

- Blue Cabinets with White Countertops: A Fresh and Modern Kitchen Look

- Green Cabinets with Gold Hardware: A Perfect Combination for Your Kitchen

Before you even touch a saw, meticulous planning is paramount. This phase determines the success and efficiency of your project.

-

Measure Your Space: Accurately measure the available wall space in your garage. Consider factors like door clearances, existing obstructions (electrical outlets, pipes), and desired cabinet dimensions. Sketch a rough layout to visualize the arrangement of your cabinets.

-

Cabinet Design: Decide on the type and number of cabinets you need. Consider base cabinets for heavier items, wall cabinets for smaller tools and supplies, and perhaps a combination of both. Will you need drawers, shelves, or a mix of both? Sketch detailed plans for each cabinet, including precise dimensions for all sides, shelves, and dividers. Consider standard cabinet depths (typically 12", 18", or 24") for easy access and efficient use of space. Online resources and free cabinet plans can be invaluable at this stage.

Material List: Based on your plans, create a detailed list of all necessary materials. This includes plywood sheets (consider the thickness – ¾" is a common and sturdy choice), cabinet hardware (hinges, handles, drawer slides), wood glue, screws, wood filler, sandpaper (various grits), primer, and paint or stain. Don’t forget safety equipment like safety glasses, hearing protection, and a dust mask.

-

Budgeting: Create a realistic budget, factoring in the cost of all materials, tools (if you need to purchase any), and any potential unforeseen expenses. Shopping around for the best deals on plywood and hardware can significantly impact your overall cost.

Phase 2: Material Acquisition and Preparation – Gathering Your Arsenal:

With your plans finalized and budget in place, it’s time to acquire the necessary materials.

-

Plywood Selection: Choose a high-quality plywood that’s appropriate for your project. Exterior-grade plywood is recommended for garages due to its enhanced moisture resistance. Consider the grade of plywood; higher grades have fewer imperfections, resulting in a smoother finish.

-

Hardware Shopping: Shop around for the best deals on cabinet hinges, handles, drawer slides, and other hardware. Consider the style and functionality you desire. Durable hardware is crucial for longevity.

-

Cutting the Plywood: Precise cuts are essential for a professional finish. If you have access to a table saw or circular saw, these are ideal for making clean, accurate cuts. Otherwise, a well-equipped home improvement store often offers cutting services. Always measure twice and cut once!

-

Sanding: Sand all cut edges and surfaces of the plywood to remove any splinters or rough patches. Start with a coarser grit sandpaper and gradually move to finer grits for a smooth finish. Proper sanding significantly improves the final appearance and ease of painting or staining.

Phase 3: Cabinet Construction – Bringing Your Vision to Life:

This is where the real fun begins! Follow these steps for building your plywood cabinets:

-

Assemble the Cabinet Boxes: Use wood glue and screws to assemble the sides, top, bottom, and back of each cabinet box. Ensure all corners are square and the pieces are securely fastened. Clamps can be helpful to hold pieces together while the glue dries.

-

Install Shelves and Dividers: Add shelves and dividers according to your design. Use appropriate shelf supports and ensure they are securely attached. Consider using dadoes or rabbets for a stronger, cleaner joinery.

-

Install Drawer Boxes (if applicable): Construct drawer boxes using similar techniques as the cabinet boxes. Install drawer slides carefully, ensuring smooth operation.

-

Attach Doors and Hardware: Attach cabinet doors using hinges. Ensure the doors are properly aligned and close smoothly. Install handles and knobs.

Phase 4: Finishing Touches – Enhancing Durability and Aesthetics:

The final phase focuses on enhancing the durability and aesthetics of your cabinets.

-

Wood Filler: Use wood filler to fill any gaps, holes, or imperfections in the plywood. Sand smooth once dry.

-

Priming: Apply a coat of primer to the entire cabinet surface. This creates a smooth, even base for the paint or stain.

-

Painting or Staining: Choose a paint or stain that suits your garage’s aesthetic and provides adequate protection against moisture and wear. Apply multiple coats for optimal coverage and durability.

-

Sealing (Optional): Apply a sealant to protect the finish from moisture and wear. This is particularly important in a garage environment.

Phase 5: Installation and Organization – The Final Flourish:

Once your cabinets are complete and dry, it’s time for installation and organization.

-

Mounting Cabinets: Securely mount the cabinets to the wall using appropriate wall anchors and screws. Ensure they are level and firmly attached.

-

Organizing Your Tools and Supplies: Now comes the rewarding part: organizing your tools and supplies within your newly built cabinets. Group similar items together for easy access. Consider using drawer organizers, bins, and other storage solutions to maximize space and efficiency.

Advanced Techniques for the Ambitious DIYer:

For those seeking to elevate their cabinet-building skills, consider these advanced techniques:

-

Dado Joints: Create strong, clean joints by cutting dadoes (grooves) in the cabinet sides to receive shelves and dividers.

-

Rabbet Joints: Similar to dadoes, rabbets are grooves cut along the edge of a board for a strong, visually appealing joint.

-

Miter Joints: Use miter joints for creating angled cuts, such as for crown molding or decorative trim.

-

Custom Cabinet Features: Incorporate specialized features such as pull-out drawers, spice racks, or pegboards to customize your cabinets to your specific needs.

Troubleshooting Common Issues:

-

Warped Plywood: Choose exterior-grade plywood and acclimatize it to the garage environment before cutting.

-

Uneven Surfaces: Use clamps to ensure square corners during assembly. Sand thoroughly to smooth out any imperfections.

-

Door Alignment Issues: Ensure hinges are properly installed and adjusted. Use shims to correct any misalignment.

Conclusion:

Building your own plywood garage workshop cabinets is a rewarding project that transforms a cluttered space into an organized, efficient workspace. By following this comprehensive guide, you can create beautiful, functional storage solutions without emptying your wallet. Embrace the challenge, celebrate your DIY skills, and enjoy the satisfaction of a job well done in your newly organized garage workshop! Remember to always prioritize safety and take your time; the result will be worth the effort.